Several folks have successfully installed electronic fuel injection on a Corvair. Here are some systems - click on a photo for a larger version.

GM Efforts.

GM Efforts.

There was at least one experimental factory adaptation of the Rochester mechanical fuel injection system to the Corvair Engine. The engine is now owned by the CPF, I'll try and get more information about it in the future.

Van Pershing posted this article with some info and photos that Ed Connolly sent to his fellow GM employee, Rosie Rosenberger.

Craig Nicol did a very nice EFI installation and shared the details with the rest of us. Below is his synopsis of the project, click the link above to go to the detail installation page, or click here to download a PDF (note - 32MB) of his install doc.

This '66 Corvair, a Monza 140-4, came with 14 carburettors. It wasn't a pretty sight and keeping even four of them fed and in diapers was just about impossible. I install EFI on street-rods for a living and got to thinking that perhaps there was a suitable EFI donor for the Corvair. V6 Multi-Port Fieros have the same number of cylinders and cubic inches, and are rated at 140hp @ 5200 rpm... it seemed to be a perfect match!

The system consists of a computer, 6 sensors, 7 injectors (6 + a cold start injector I don't use), a high pressure pump, pressure regulator, throttle, idiot lights, and an improved charging system. The 140 cylinder heads' intake manifold has been bored to allow aftermarket injector bungs to be welded on. A narrow dispersion angle injector is required due to the long spray distance. The HEI, all-electronic distributor is a mix of Corvair and Fiero. Air distribution duties are handled through the courtesy of a 4-bbl manifold. The Monza fuel tank has a modified S-10 Blazer pick-up and high-pressure pump. They're mounted in a top-side flange cut from the Blazers' tank. A Fiero wiring harness, extensively modified, provides neural connections. And, just for fun, I put the "check engine" and "upshift" lights are in the Monzas' fuel gauge.

The performance is really pleasing. It pulls like a turbo at the top and has bunches of bottom end torque. I haven't checked economy yet but it should be in the mid 20s. My next modification will be a 6 throttle system and a more up-to-date cam with better idle quality than the original "304". VAIROOM!!!

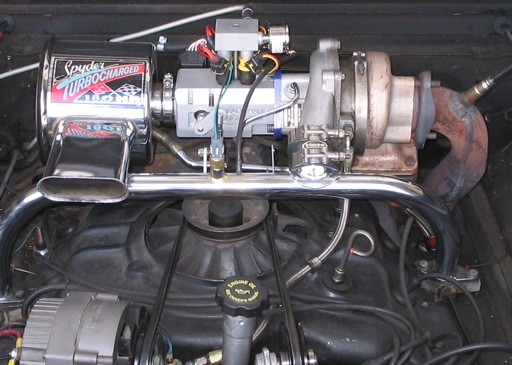

Chuck Riblett's Blackhawk Engineering develops EFI on the Corvair, here's his post on a system for a turbo Corvair engine, along with photos of both the turbo and 110 systems. See the Blackhawk Engineering web site for more details.

I have been driving a turbocharged Corvair with fuel injection controlled by a MegaSquirt controller for about a year. This is basically a 95 HP engine with forged pistons, Otto cam, 180HP turbocharger and 180HP distributor with SafeGuard ignition. I machined a throttle body that fits between the turbocharger and the original air filter housing. The throttle plate diameter is 1.8 inches compared to the YH carburetor throttle plate of 1.5 inches resulting in much greater airflow than the carburetor.

I have never driven for best fuel economy, but I have kept records. With fuel injection and a wide band oxygen sensor the car has been getting 20-22 MPG despite using the increased performance. For comparison, with the YH carburetor and original metering rod and jet, I got 13-16 MPG. After much testing using a narrow band oxygen sensor and machining custom metering rods, I was able to get 17-19.5 MPG using the carburetor.

Setting up the fuel tables is fairly easy if you use a wide band oxygen sensor for feedback. The baseline tables are created based on the engine size and the number and flow rate of the fuel injectors. With the MegaSquirt I controller, you drive around collecting data on a laptop computer with MegaTune software. Then you use MegaLogViewer to modify the fuel tables. With MegaSquirt II, AutoTune is available to adjust the fuel tables as you drive. I believe that you can easily pay for the $200 wide band oxygen sensor system with the improved fuel economy.

The engine started the first time as soon as the fuel lines were pressurized. After setting the idle speed, I was able to drive the car gently and collect data. After a few drives around the neighborhood collecting data and then modifying the fuel table, I was able to drive the car normally. I continued to make small adjustments whenever I noticed an area that could be improved.

The engine now starts immediately every time without any of the flooding and vapor lock problems of the carburetor. The increase in torque available for passing at highways speeds is truly impressive.

The hardest part of the installation was routing a fuel return line and connecting it to the gas tank. The most time consuming task was fabricating a wiring harness. I mounted the electronics on the shelf above the transaxle (early coupe) away from the engine compartment heat.

The original version of the throttle body had the injectors before the throttle plate. This resulted in fuel dripping out at the air filter flange particularly in cold weather. For the current version, the injectors are mounted after the throttle plate. Since the injectors are mounted on the vacuum side of the throttle plate, there have been no fuel leakage problems.

I don't think that a low-pressure throttle body with the injector(s) above the throttle plate can be mounted sideways without fuel leakage problems.

Future plans call for using a MegaSquirt II controller for ignition control. I am also working on throttle bodies for a 140HP engine in another car.

Chuck