There are quite a few things that are legal to modify in Street Prepared, and unless you are lucky enough to have a car that's fully prepared, you'll want to make some changes. One thing to remember is that the Corvair was designed to deliver good cornering and a good ride at a reasonable cost. One problem with this is that the comfortable ride slows the reaction time of the suspension.

Consider the car entering a turn. The soft springs allow the suspension to roll, the shocks may allow an oscillation before the car settles, and the bushings deflect as the force builds. All this takes time, not a long time, but in a 60 second run, it doesn't take much. We want the car to reach a stable cornering state as quickly as possible, even at the expense of some loss of maximum grip.

Springs are the basic component that affects the handling of your car. First, they hold it off the ground, but their main purpose is to keep the body from being affected by wheel motion. So, they resist both body roll and pitch. A spring's stiffness is measured usually in lbs/in, and is often referred to as rate. It is my opinion that most Corvairs do not have enough spring rate for today's tires. For reference, the Trans-Am race cars of the 60's were capable of about 0.9g on the best tires available. Many of the Stock and Street Prepared cars of today, running on street legal tires, are capable of 1.0 or more lateral g's. Another thing worth noting is that a stock Corvair was capable of about 0.7g on its stock tires.

Given that, it seems to me that more rate is a good idea. Now, it is often said that using a softer spring with large sway bars will produce a car that is not too harsh, but still capable of good handling. IMHO, this is the way to go, *but* we need to count in that we will be able to pulling a bigger g number in *braking* too.

According to my measurements, the stock late model HD spring rate for the front is 260 lbs/in, rear is 225 lbs/in. Note that the front suspension has a mechanical advantage over the spring which reduces the effective rate at the wheel to about 40% of the spring's value, but the rear acts almost directly on the wheel. For Stock class, you can legally put these on your car, since the HD suspension was always a separate option every year it was available. Cut one coil, these are a good choice for a car that sees a lot of street miles and is only occasionally autocrossed in either SCCA SP, or CORSA IS or SM, but IMHO you will get too much body roll with them.

Early models can use the stiffer springs up front, but the ideal solution in the rear would use the soft coils and add stiffness only with the rear leaf.

A sway bar (aka anti-sway or anti-roll bar) is just a torsion bar whose ends are connected to the wheels and middle is mounted to the body (actually, on a live axle car you can mount the middle to the axle and the ends to the body with the same effect) which then resists body roll without adding any spring rate. Since the bar is usually in a bushing which has some compliance, it also will not resist small bumps, but will start working once the body has rolled a certain amount.

When introduced, the Corvair didn't have any sway bars at all. In '62, an HD suspension option was introduced which included a front sway bar (and heavier shocks and springs), and all '64 and later Corvairs came with a front sway bar standard, but none came with a rear bar. For stock class folks, you can change the front bar to whatever you like, but you can't add a rear bar, and if you're looking to reduce the understeer this means going with a smaller front bar, such as the '62 bar. For SP, I wasn't willing to increase the body roll at all, and since both bars are free, I've added a rear sway bar. There are two designs of rear bar for the late model, by Addco and Crown. There are two problems with the Addco bar:

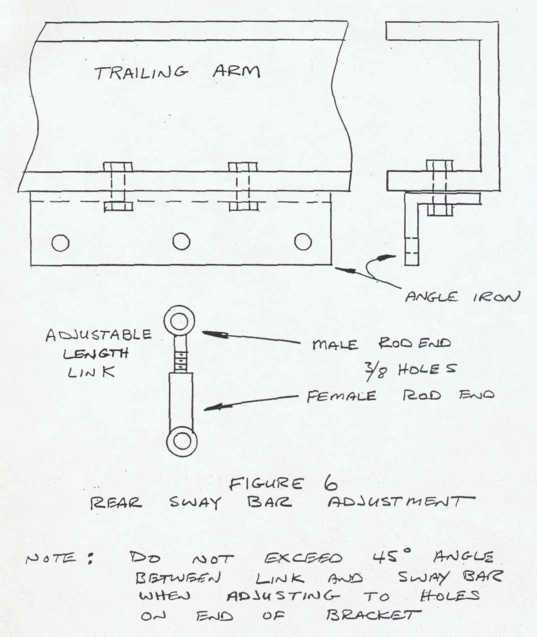

Problem #1 - This is fairly well known in the 'Vair racing community. The way they have you mount the bar uses a bracket that bolts to the frame, and a rigid mount that bolts onto the trailing arm. The problem is that this effectively triangulates the trailing arm to the frame, making the rear spring rate *very* large. This causes dramatic oversteer, fun to watch, but a bad plan in general. The fix here is to throw the control arm brackets away and get 2 pairs of male/female rod ends, screw them into each other, giving you a flexible "dogbone" shaped link. One end bolts onto the trailing arm, the other attaches to the end of the sway bar. Here's a good drawing from Jim Schardt's Stinger Prep Manual:

Problem #2 - The brackets that bolt to the frame hang down a loooong way. In my case, I was left with about 2 1/2" of ground clearance! The problem is that the inner mount to the body is a piece of angle iron and the sway bar bushings bolt to the side of it. The Crown brackets have an extra inch or more of clearance, since the bar bolts to the bottom of the bracket. Matt Nall made some up out of 1/8" steel strap, see photo at right.

Crown also made front bars, the inner mounts are especially worth installing even on a stock bar, as the stock inner mount has a rubber bushing on *both* ends. Because of this, I suggest using the Crown style bars. You can look for a set used, or check with Bob Coffin.

For early models, the front sway bar setup is essentially the same as the late. You can use a stock bar, including a late one, on the front or you can install an aftermarket one. A rear sway bar is generally a bad idea - with a swing axle suspension it's often best to keep the rear roll resistance as low as possible.

Let's start by saying shock absorbers don't really absorb shocks. The springs do. The Brit car guys call them dampers, which is much more descriptive of what they do, they keep the spring from over correcting when a bump or dip is encountered in the road. They also help tremendously with transitional handling, since the car will not take as long to come to a final roll position in a corner. The car will also feel much better to drive. Finally, stock class folks can use shock stiffness to help balance the car, since you only have that, the front sway bar, and tire pressure to adjust.

Standard Corvair steering has been described as winding a clock. That probably meant more in 1960, but let's just say it's slow :-) The factory offered a fast ratio steering option starting in '65, since then Flaming River has come out with a replacement Corvair box that can be installed in any Corvair with the correct adapter kit.

The aftermarket has offered several variations on a less expensive theme - faster ratio steering arms. Mike Harrison had a display at the Carlisle convention, a photo of it by JR Read appears to the right (click for larger image).

Each of the suspension arms in the Corvair has rubber bushings stock in at least one end. They are used in place of a proper spherical bearing to lower the cost and to isolate small vibrations. They also have the advantage of not requiring any real maintenance for a relatively long time.

However, they have a big disadvantage in that they can deform, and under extreme loads this has two negative effects. First, this deformation takes time, and second, they make the suspension describe a motion that doesn't follow the designed curves.

What would solve the problem would be to replace the bushing with a bearing that could rotate in all three axes. Unfortunately, we are limited in SP by the rules to replace the bushings with a non-metallic bushing of the same design but any material. If the bushing only has to rotate in one axis, such as the pitman arm bushing, replacing the bushing with a relatively stiff material such as nylon works well.

In the case of a bushing which must rotate in more than one axis, such as a rear lower control arm bushing, we want a bushing which has just enough give to allow the arm to rotate, but no more than we absolutely need. Most of the Mustang/Camaro folks have used polyurethane for these applications, and some have recently been introduced for Corvairs. I've constructed a bushing page of which nylon ones can be used, along with what's available aftermarket.

If you are going to be running in Prepared, you may install spherical bearings in place of the bushings. You can find the details in Jim Schardt's Stinger Prep Manual, under "Suspension".

Once you've got all these cool parts in place, you'll need to align the car to use the tires to their maximum. Alignment plays a very important role in how well the car handles, and if you really want to understand how the alignment specs can influence the handling, I suggest you read a book devoted to the subject, since I've only included a brief description of what effects what.

There are three values for each setting: Factory is from the '65 shop manual ('66 up is a even more conservative). Street is a bit radical, but the car won't be too twitchy and you won't kill your street tires. Autocross is what I found worked pretty well for me, you shouldn't consider it gospel, tho, just a good starting point. Also, remember that I am using *radial* tires, these values will not work very well on bias-ply tires (such as Hoosier Autocrossers). For you early owners, the factory specs are a bit different, but these values should apply as a starting point for a more performance minded car.

Factory. Front: Positive 1 degree +/- 0.5. Rear: Negative 1 to zero degrees.

Street. Front: Negative 0.5 degree. Rear: Negative 1.0 degree.

Autocross. Front: Negative 1.0 degree. Rear: Negative 1.5 degrees.

Factory. Front: Positive 2 +/- 0.5 degrees.

Street. Front: Positive 4 degrees.

Autocross. Front: Positive 4 degrees.

Factory. Front: 1/4" to 3/8" toe in. Rear: 1/8" to 3/8" toe in.

Street: Front: 1/8" toe in. Rear: 1/8" toe in.

Autocross: Front: 1/8" toe out. Rear: 1/8" toe in.

At this point many Corvair racers have noted flexing in various places. Take a look in the Stinger Prep manual for some thoughts. The big one is the center link - big fat tires tend to flex the link. You can modify it using these directions from Bob Coffin:

Weld a piece of 1" by 3/16 thick angle steel to the center part of the relay rod with a series of 3/4" long Mig welds, about 1&1/2 inches apart.

Here's the modification, done by Rick Norris for his track car, note the angle iron between the inner tie rods:

Rick made a new one for a friend's car and shot a few photos of the process:

So far, everything discussed here supposes that you are going to run a suspension with stock geometry, that is, the suspension components are of stock dimension and the points where they attach are in the stock locations. However, if you're running in a class that allows you to change these things, you can improve the stock suspension for a performance application. This point is important - remember that the Corvair was designed as a street car. A racer probably does not have to be too concerned with potholes or speed bumps. The best known part to change the geometry is the Crown rear lower control arm bracket.

The Crown bracket was designed for use in a Corv8, and was meant to keep the rear tires flat on the ground under hard acceleration. As delivered, the Crown bracket removes all camber gain, that is the tires now move straight up and down relative to the body, rather than cambering to match the angle the body has to the ground. This change is good for a drag car. The stock brackets have a correct camber curve for cornering, however this leaves us with a rather high roll center.

As a compromise between roll center and camber curve, some racers use a redrilled Crown bracket which is a compromise between the roll center and camber gain issue - BTW, this is always a suspension design issue, you have to decide what you're designing for. Bob Coffin suggests re-drilling the mount holes 3/4" higher. Note that the folks who researched the change in dimension are road racers. IMHO, the Chevy design is a better compromise for a street car which will see a lot more wheel travel than a racer. One big advantage of the Crown bracket is that it's considerably stronger than the stock piece, so you will gain a bit there, and it can also be re-drilled to equal the stock dimensions for a street car or SP class autocross car.

The above discussion of just this one piece leads to my suggestion that you read a suspension book like Fred Puhn's book How to Make Your Car Handle.

You will probably reach a point where you've done a whole bunch of the modifications discussed here and some others, only to find that the car over or understeers more than you'd like. The following lists of items are common ways to change the balance of the car: